Precision Hydraulics for Passenger Lifts

When elevator downtime is not an option, our hydraulic hoses and components deliver flawless performance under constant cyclic loads.

Precision Hydraulics for Passenger Lifts

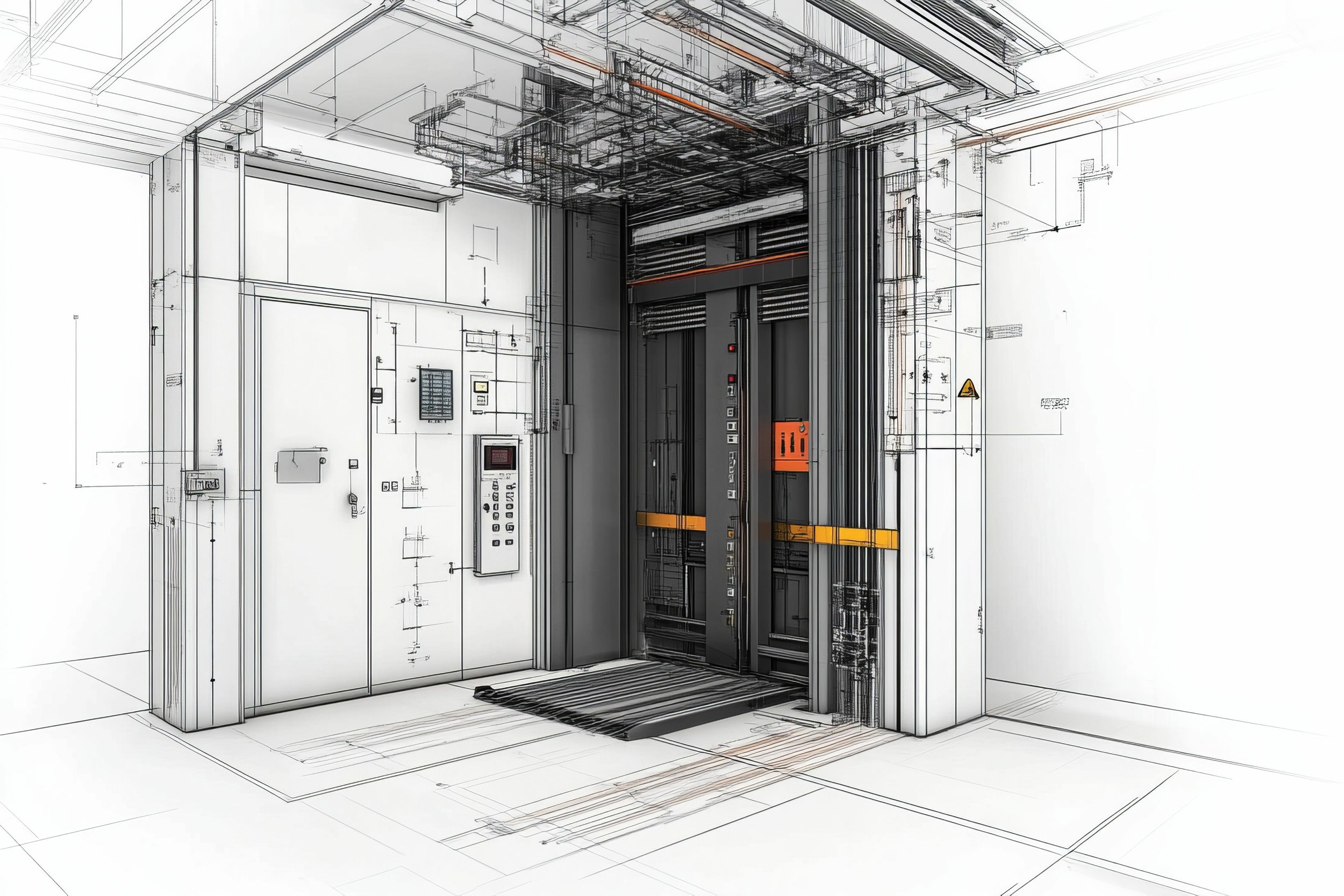

Passenger lift systems demand absolute reliability, quiet operation, and full compliance with safety standards such as EN 81‑20/50. For OEMs and maintenance providers, every component must perform flawlessly under continuous cyclic loading—often within the constraints of limited machine-room space.

Request a bespoke quote for passenger lift hydraulic systems

Call us: 0333 000 2040

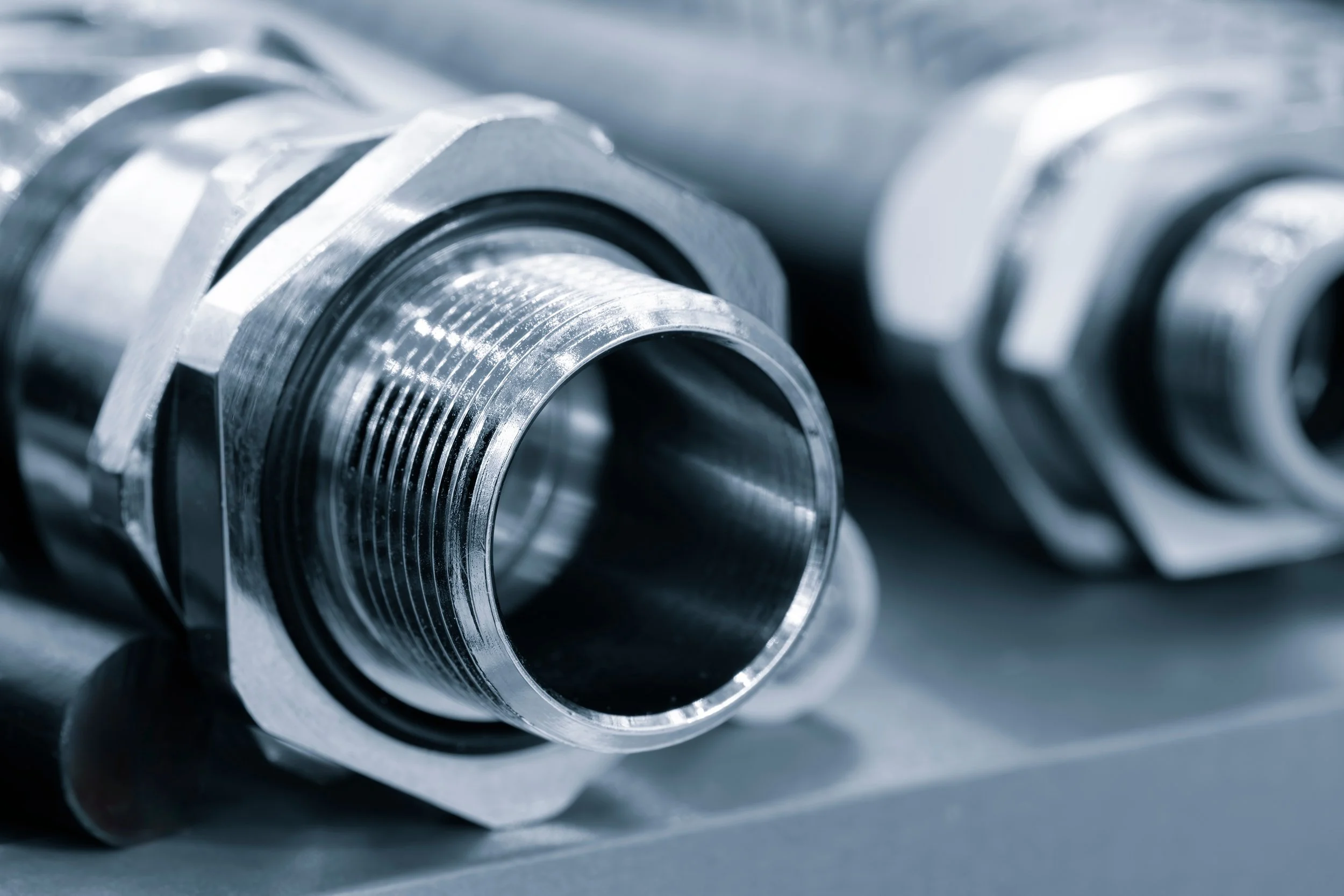

Regent Trist supplies high-quality hydraulic hose and tube assemblies engineered specifically for lift applications. Our solutions are designed to support efficient installation, reduce system noise and vibration, and meet the strict traceability and certification requirements expected by the industry.

Industry Challenges

Compliance with EN 81‑20/50

Vibration‑induced fatigue and noise.

Limited machine-room space.

Our Solutions

Bespoke tube and hose kits tailored to your lift architecture

Industry-certified hoses and tubes, tested for endurance

Rapid turnaround to keep lift downtime to a minimum

Why Regent Trist?

ISO 9001 traceability on all parts

Rapid assembly and fulfilment

CAD integration with client drawings

Bespoke hydraulic kits to suit all lift configurations

Lifecycle support and managed replacement schemes